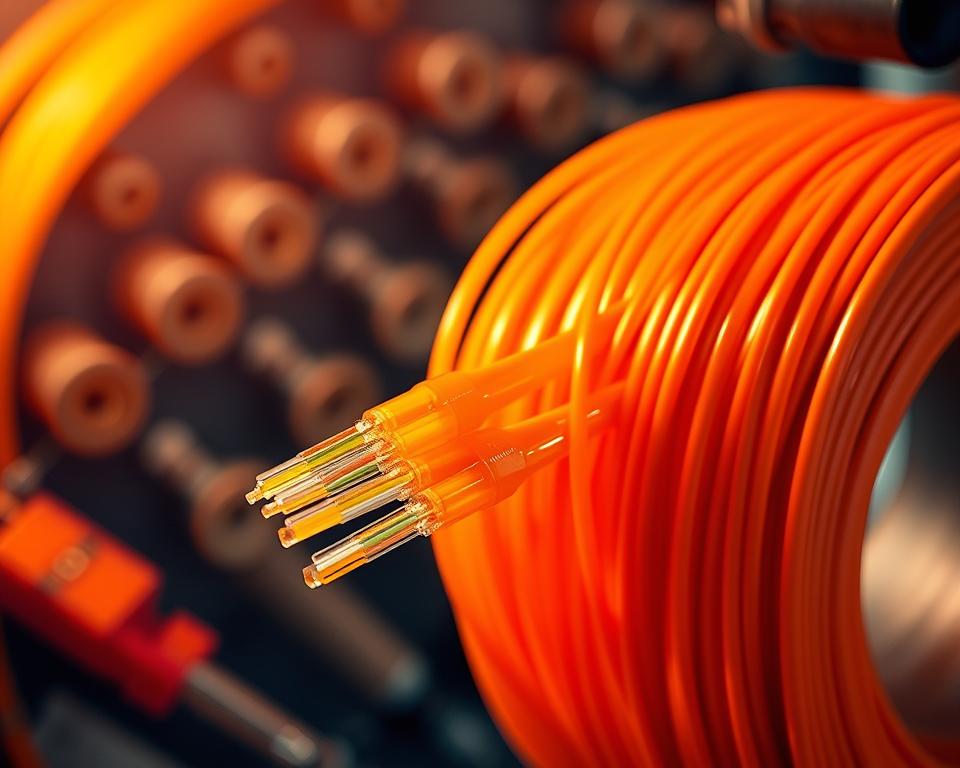

FTTH Cable Manufacturing Line – Cutting-edge Production System

Have you realized that contemporary light-transmitting wire networks are capable of running at velocities of up to 190 m/min? This astonishing productivity is made possible by sophisticated production methods designed for high-speed production.

These systems are constructed to process diverse wire variants, including drop cables and firmly insulated cables. Their efficient construction, typically below twenty-six meters, suits them well for modern facilities.

Incorporation into intelligent production networks guarantees smooth operations. Through MES/ERP connectivity, these fiber secondary coating line fabrication lines provide unmatched exactness and performance. This makes them a top choice for enterprises seeking to lead in the telecommunication sector.

Overview of the FTTH Manufacturing Line

Efficient manufacturing setups are crucial for satisfying the rising demand for dependable links. These systems are designed to create premium glass-fiber cables that drive modern networks. By leveraging modern innovations, they guarantee exactness and rapidity in every step of the manufacturing process.

What is an FTTH Cable Production Line?

This fiber-to-the-home production system is an integrated system for manufacturing fiber-to-the-home drop cables. They include bare fibers strengthened by steel or FRP, merging with safeguard coverings. This produces a durable and efficient solution for rapid broadband links.

It works with multiple materials, such as PVC, LSZH, and PE polymers. This versatility confirms it accommodates varied market demands. Furthermore, the 4-head fiber pay-off system provides exact tension management, keeping stability within ±0.05N.

Why Choose Our Advanced Manufacturing System?

Our system distinguishes itself for its precision and efficiency. Below are the advantages:

- Handles multiple cable types, including 2.0×3.0mm and 2.0×5.0mm drop cables

- Works with LSZH, PVC, and PE covering substances for adaptable uses

- Boasts a quad-head payout mechanism controlling tension between 0.4N and 1.5N

- Provides throughput up to 9km/h specifically for 2.0×3.0mm cables

Such attributes guarantee streamlined functionality and premium production. Thus, it becomes the optimal option for enterprises seeking a competitive advantage in fiber networks.

Core Attributes of Our FTTH Cable Fabrication Line

Contemporary production setups are revolutionizing the way fiber wires are made. Our high-tech system integrates precision, efficiency, and cutting-edge technology to deliver premium performance. The following outlines the remarkable components that position our system at the forefront.

Accurate Extruder Coupled with an Adaptable Head

Central to our setup is a specialized 50mm extruder designed for precise material distribution. It secures consistent quality in all cables manufactured. The modifiable head supports smooth personalization, accommodating different substances like PVC, LSZH, and PE plastics.

Using OMRON thermal regulation, the system maintains an accuracy of ±1°C. This level of precision guarantees optimal performance and reduces waste, making it a cost-effective solution for manufacturers.

Automated Fiber Dispensing with Strain Management

The automated fiber unwinding unit operates under a controlled tension of 0.4N up to 1.2N. It guarantees gentle fiber management and curbs potential damage while manufacturing. The dual-wheel capstan system, with diameters of 640mm and 400mm, further enhances stability and control.

This feature is particularly beneficial for producing high-quality fiber cables, as it ensures consistent tension throughout the process.

Self-Operating Rewinding and Material Acquisition Mechanism

Our two-shaft collection mechanism accommodates spools between PN400 and PN630, ensuring versatility across different production demands. The automated line-receiving feature eliminates the need for manual rewinding, saving time and reducing labor costs.

Additionally, the X-type laser diameter gauge provides real-time quality control, ensuring that every fiber cable meets stringent industry standards, yielding resilient and dependable items.

State-of-the-art Technology Powering the Production Process

Trailblazing technology is transforming the fabrication of optical fibers. Our equipment is engineered to provide exactness, consistency, and productivity, to achieve optimal outcomes on all orders. Outlined below are the breakthrough characteristics that distinguish our apparatus.

Worldwide Industrial PC and PLC Integration System

The backbone of our system is the FiberCAN PLC integrated with an industrial computer terminal. It facilitates uninterrupted functioning with instant oversight. It enables exact fine-tuning, thereby elevating the caliber of each cable fabricated.

Operating at a mere 35KW/h under standard conditions, it offers low energy consumption. This reduces operational costs while maintaining high performance. The 9m cable accumulator ensures uninterrupted processing, minimizing downtime and maximizing productivity.

Superior Stability and Trustworthiness with Leading Brand Elements

We utilize top-quality elements from reputed brands like OMRON controllers and worldwide motor suppliers selected due to their robustness and accuracy, promising lasting dependability.

The steel wire reinforcement and advanced FIMT handling mechanisms provide added strength and stability, so that each fiber cable complies with strict quality and functionality standards.

MES/ERP Connectivity Integration

Our equipment integrates seamlessly with MES and ERP systems, enabling real-time production tracking. It provides complete visibility and operational efficiency across all stages.

Companies are enabled to track performance data, refine processes, and minimize resource loss, which makes it the optimal selection for contemporary production environments.

| Aspect | Benefit |

|---|---|

| FiberCAN PLC Control System | Accurate control and immediate supervision |

| 35KW/h Operational Energy Use | Low-cost energy performance |

| 9m Cable Accumulator | Seamless operation |

| OMRON Controllers | Reliable and exact performance |

| ERP Integration | Real-time production tracking |

Uses of the FTTH Manufacturing System

Modern fabrication systems are revolutionizing the production of dependable fiber networks. These systems are designed to meet diverse industry needs, delivering versatility and exactitude for each use case. The following outlines the primary applications of this state-of-the-art system.

Manufacturing Home Drop Cables

Our system excels in manufacturing drop cables, which are essential for high-speed internet connections. It manages support wires from ø0.4 to ø1.0 to guarantee robust performance. A core shaft opening of ø56 facilitates flawless compatibility with PN400 dispensing reels.

Important elements consist of:

- Combined FRP and diminutive steel wire payout to enhance strength

- Portable die backing for rapid setup modifications

- Adaptability to meet interior as well as exterior standards

Producing Both Tight Buffered and Loose Tube Cables

It proves perfect for manufacturing both closely buffered as well as loose tube cabling systems. Exhibiting a mere 0.02dB/km loss, these cables offer superior signal integrity. Their careful stranding guarantees exact assembly, and processing ø1.2mm steel wires further enhances durability.

Customizable Solutions for Various Cable Types

Adaptability is a defining feature of our production line. It accommodates numerous substances and layouts, ensuring appropriateness for varied uses. Whether you need indoor or outdoor cables, our equipment delivers consistent quality and efficiency. This adaptability ensures that businesses can meet specific requirements without compromising on performance.

Key Gains from Our FTTH Production Line

Investing in advanced manufacturing systems yields numerous benefits to enterprises focused on fiber technology. They are engineered for operational efficiency, cost reduction, and superior product output. Here are the principal merits that render our equipment indispensable for today’s production facilities.

Improved Operational Speed and Yield

Our system ensures Fiber draw tower high-speed operations, achieving outputs of 7-9km/h depending on the cable size, allowing businesses to meet growing demands without compromising quality. Additionally, automated spool handling diminishes labor effort, enhancing time efficiency and resource use.

Budget-friendly Fiber Optic Setup Solutions

Its efficient use of 35KW/h power curtails energy expenses. A user-friendly design with a 1000mm operational height boosts both comfort and productivity.

Consistent and Uniform Cable Finishing

Exact molding delivers a sleek and consistent exterior on all fiber products, minimizing additional loss to ≤0.02dB/km, ensuring top performance. Steel supports fortify the cables, rendering them robust for multiple uses.

| Characteristic | Benefit |

|---|---|

| Rapid Throughput | Increased operational efficiency |

| Efficient Power Usage | Reduced operational expenses |

| Negligible Attenuation | Top operational efficacy |

| Optimal Operator Work Level | Ergonomic design |

Summary

Cutting-edge optical cable manufacturing is establishing fresh industry norms. Thanks to exacting design and integrated smart features, these systems offer unparalleled dependability and performance. Operating at up to 190 meters per minute, they guarantee significant investment benefits.

Our systems also come with dedicated technical support and customization options to meet specific needs. Whether increasing capacity or improving product integrity, our technology ensures you maintain a competitive edge.

Set to upgrade your manufacturing capabilities? Contact us today to explore tailored solutions that fit your requirements. Experience the future of fiber optic technology with our industry-leading systems.